In the rapidly-evolving world of direct mail printing, we are constantly striving to stay on the leading edge. This means more than having the latest and greatest technology. For us, it’s more about how we use the technological tools in our toolbox to craft creative solutions for our customers’ ever changing needs.

Digital printing has revolutionized aspects of direct mail printing, and there are a plethora of options. Because of the fast-paced evolution of digital printing, there is some confusion about the differences between inkjet and toner-based print technologies. It can be a challenge to get an accurate lay of the land. We’re generally device-agnostic and solution-oriented, seeking to design around your quality needs and objectives. But we think it’s still important to have some of our wealth of knowledge available for customers. In that spirit, we put together some brief thoughts on the differences, strengths and weaknesses of each.

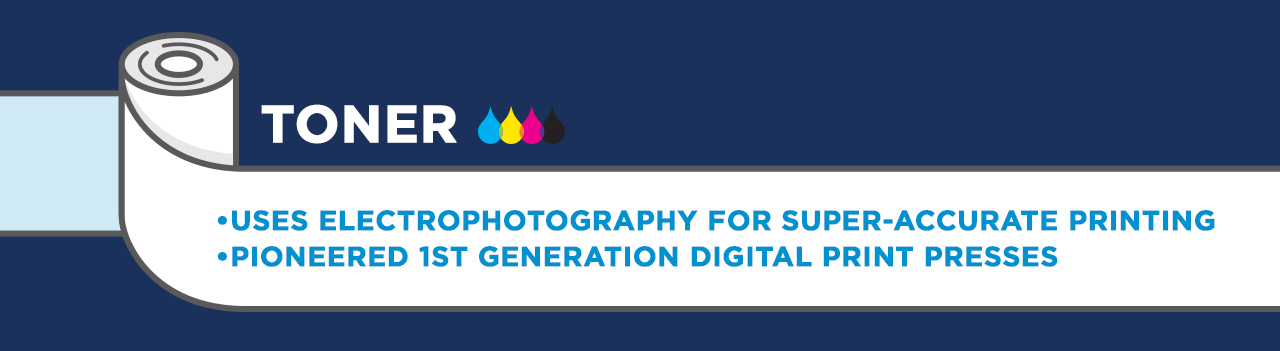

Toner-Based Printing

“Toner-based” is a catch-all term for any laser, toner print platform that uses toner technology, electrophotography or Electroink to drive print dots into super-accurate positions. Toner-based presses were the first generation of digital printing, and the platform has had time to mature, with incremental improvements continually building upon the base technology. This process is degenerative, which means that the components critical to printing a consistent image wear out at different cycles—requiring constant calibration and service to maintain that quality.

With toner-based digital printing, the quality is typically very high, with precision dot application achieved via an intermediary process like an imaging drum or belts. These presses are able to reach a wider color gamut than most inkjet presses, though SPC’s Canon ProStream presses are an exception. Most toner-based presses can run a fifth station—clear, gold, red, one-off colors. They also have the ability to run a broader range of specialty stocks and substrates—Teslin, plastics, toothy stocks and other options, with thicknesses up to 14pt.

However, toner-based systems generally run more slowly than inkjet, with somewhat higher click costs per sheet. This premium price is inherent in the mechanical processes of the presses and their design, as well as the higher cost of toner versus inkjet ink. This, coupled with less uptime on these complex presses, presents a tradeoff depending on a customer’s project goals.

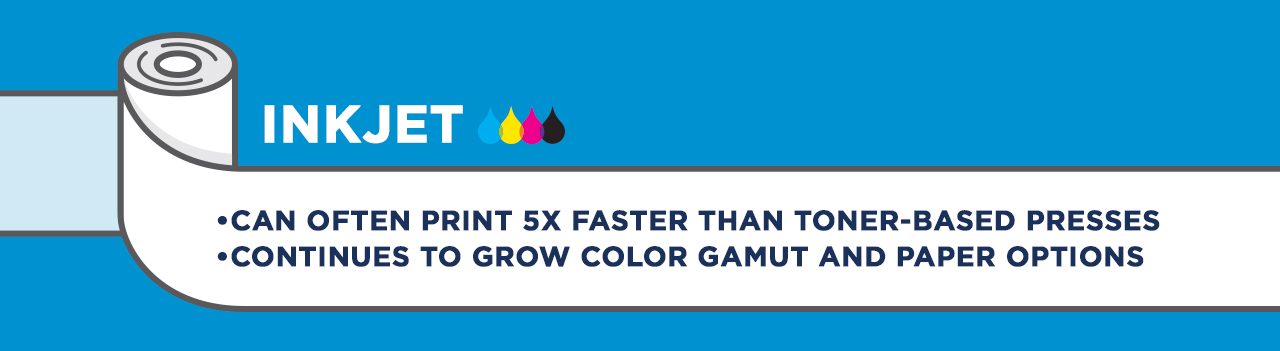

Inkjet Printing

Inkjet technology has ushered in a world where we can print five million pieces with full, four-color printing and variable data—in quick turnaround, utilizing robust client data for greater impact and responses. It is a game-changer both for us and the direct mail industry.

The biggest benefit of cutting-edge inkjet technology is speed. Inkjet systems run at faster speeds—as much as five times faster than toner-based systems. These speeds are possible because the process allows quicker application of ink to paper. Many inkjet presses also have more nozzles for ink deployment and additional dryers—which are crucial, as drying times are key (since inkjet inks are generally water-based). These print speeds make inkjet very cost-effective over the course of larger runs.

Inkjet color quality grows more robust every year and can match that of toner, especially in color consistency. At SPC, we feel that because of these advances, inkjet can more than adequately cover all of our customers’ color needs. Despite the positives of Inkjet technology, it has its limitations. Inkjet compatible paper stocks are fewer than those available for toner-based devices. Additionally, some inkjet presses require treated paper to provide a uniform surface for the water-based inks, which can limit the types and thicknesses of stocks. Currently, SPC inkjet presses don’t run anything heavier than 10-point paper stocks. However, the Canon ProStream and i300 presses we utilize at SPC have more flexibility than most in the inkjet realm.

Not all inkjet technology in the marketplace is the same, as different variations weigh in at different price points. Marketers can find a wide range of quality and output, and SPC is at the high end of the spectrum. Many printers will claim to “sell inkjet” as if the technology is a marketing magic bullet, while SPC focuses on brand quality direct mail that is just in time for your marketing plans.

There is a place for both technologies in the portfolio of any good marketer, and at SPC, we aim to use whichever fits the needs of our customers—in timing, costs, reach and quality. But what does tomorrow look like? When I gaze into our crystal ball, I think the future looks like fully variable printing. Dynamic data use and full customization often yields triple and quadruple the response rates, and inkjet might be the key to making data-driven direct mail the industry standard.

Adam LeFebvre

President